Material-Details: PLA

PLA is a biodegradable thermoplastic prduced from corn.

Because of this it is mostly used for Prototypes for short term use to safe waste.

PLA is resistant to most chemicals, even aggresive ones like Alcohol and aceton.

PLA has the most distortion free print of all FDM materials. Thats why we recomend it for Parts with big, flat designs

that would have the risk to Warp during print in other Materials.

Because of its Manufacturing in large quantitys due to it´s widespread use in professional- and home- printing aplications

this material is cheaper than most other 3D Printing technologys.

Contrary to popular belief, PLA decomposes only insignificant faster than "normal" plastics, even when used outdoors.

The biodegradability takes place only under controlled conditions (eg. in a compost plant).

Pro & Contra

- Strucuraly strong

- Biodegradable

- Nearly Warp-free print

- Cheap

- Heavaly chemical resistant

- Low resolution due to FDM technology

- Vulnerable to temperature

- More brittle than other plastics

- No flexibility

- needs supportmaterial for overhangs

Shipping within 5-8 Working Days

Design specifications

Minimum wall thickness

1mm

Smallest detail

0,3mm

Maximum dimensions

250 x 250 x 300 mm (up to 1,5 meter on demand)

Prioprity service

When ordering before 12 noon we ship within 2 working days

Price: 30 % extra charge

Price calculation

We want to be transparent! So we tell you how we calclate the price of our Parts.

0,57 € / cm³ * used material. All costs for Supportstructures and renoval of the same are includet in this price.

* May Varry on Parts with a high amount of supports or postprocessing.

Typical use

PLA is typicaly used to print large prototypes because of its warp resistans and low shrinkage while Pinting.

Also due to its biodegradability it is used to manufactuire onetime use Prototypes:

Sometimes it is used in Longterm aplications if temperature and flexibilit isn´t an issue.

Technology

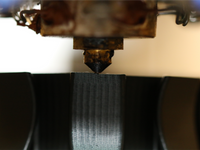

PLA is manufactured using FDM technology.

FDM means fused deposition modeling.

This technology uses an extruder to "stack" layers of molten plastic. More on this down below in " the procedure".

FDM is one of the simpler 3D Prining technologys. Because its ease of use its one of the most widespread technologys out there.

FDM got famous due to its use at home in non professional 3D Printing application.

The big advantage of this technology is the high variation of materials and the possibility to produce prototypes in original material (thermoplastics).

Also there is the possibility to infuse the material with materials such as carbon fiber, glass etc.

Another advantage is the possibility of closed cavitys within the parts to safe on matarial an weight.

FDM isn´t well siuted for small parts because they tent to overheat while printing.

The procedure

a 3D model (STL file) is broken down into Layers of 0,1- 0,3 mm depending on the needed details and Partgeometry.

A fully outomated programm now writes the toolpath for the extruder head similar to cnc milling technology.

This programm, containing a fwe hundrets up to millions of line of code is now feedet to the printer.

The material, in form of a plastic wire of the used Materail, is now feedet to the "hotend". there it gets heated to a temperature of around 180 - 350 °C depending on the material.

The material gets melted and get pressed out of the nozzel by feeding more Material in the hotend.

The cnc controlled head now starts moving. While doing that the Matial feed is precicly balanced with the movent of the head and the layer gets "drawn" on a printing bed. Outlines first, then filling. Onece the first layer is finished the head moves up the demanded layerhight and repeates the process with the next layer.

Every layer gets layed down on the last one. Over Time a 3 dimensional shape gets created.

If there are overhangs in the part, the newly printed layer wouldn´t have a surface to get layed on. Thats why we use removable Supports that hold up these areas while printing.

These will be removed in postprocessing and consist most of the time out of chemical solvable materials to speed up postprocessing.

Additional Informations

- PLA ,as all FDM plastics, are not approved for direct contact with food.

- Components made from PLA should not be used without additional protection in outdoor areas.

- PLA is not appropriate for use in high ambient temperatures. From about 50 °C the material is deformed (eg. direct sunlight and in parked cars).